Tailor TOSCAST to Improve Your Die Casting Productivity

ELK GROVE VILLAGE, IL, January 20, 2021

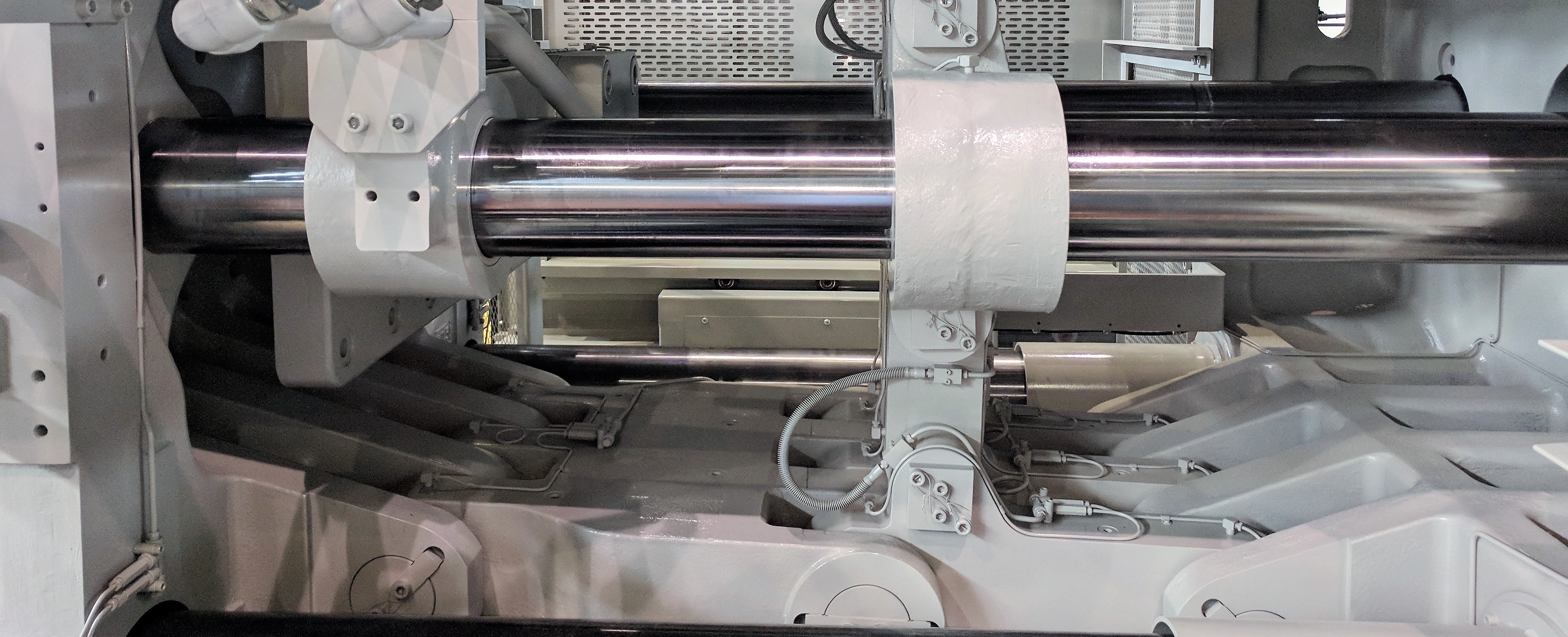

For years, die casting machines have offered digital control options making operators more efficient and improving throughput, but a gap still exists. These machines can only do so much before a human needs to step in to identify problems, fix them, and restart production.

Enter one of the best-kept secrets in the die casting world - Shibaura Machines TOSCAST Production Monitoring. This advanced control system translates the skills and labor of humans into a user-friendly, high-performance tool to help increase productivity.

Digitalization of Production Management

TOSCAST allows you to intelligently further automate your production. The system encompasses condition setting, monitoring, and management under two product monitoring screens to improve production efficiency and ease operations and maintenance.

Product Monitoring Screens

These screens allow operators to put in the information of what they have done, how they have done it, and the time it takes to complete along with issues that have been encountered.

1. Cumulative Production

Think of this screen as how many parts you want to make in a lot. It will not only show you how many parts are left to be made but accounts for total shots and warm up scrap all on one screen.

Additional highlights include:

-

- Warm-up scrap setting displays the total quantity of products created by casting with high speed off and intensification off and created by casting during startup operation together with the quantity discharged due to the quality settings.

- You can also load in manually up to five different defects in parts that the machine can not see (this could include cold flow, greased, cracked, heat checked, etc.).

- Manually inputting for a production stoppage can be done through cumulative settings, the plant can customize this section to fit requirements.

- Quantity until the end displays the remaining quantity by subtracting the current production quantity from the planned total production quantity.

- Automatic end control will automatically stop the cycle when the planned total production quantity is reached.

2. Shift Production Management

This screen complements the cumulative production screen. Shift production management allows for the same data found in the cumulative, but specific to operator shifts.

The shift time can be set so that the stop operation is performed automatically after casting of the production quantity is completed for each shift. The system will allow for up to three days back to review past shift data.

Tailor TOSCAST to Your Precise Needs

We know every production floor is different. From your processes to the parts you produce, TOSCAST allows you to input criteria to ensure you get the efficiency, quality, and automation to suit your unique needs.

Quality Condition Settings

Using the quality conditions, you can choose from 48 items to input with upper and lower limit settings for the conditions. This allows the system to better understand what is a quality part.

This setting also allows you the ability to decide what to do with the output. This feature can be turned off or choose from one of several operations, including using an alarm.

Thermal Control Settings

Thermal control allows you to add temperature requirements (if your machine has it), similar to the quality conditions high and low settings. This will enable things to turn on and off. For example, heaters or valves can start automatically or you could program the die casting machine not to assume the mold in the machine until it is at a proper working temperature which you have input.

This feature is very helpful with a non-controlled die where you don’t have a heating system turning on and off cooling water or heat. For example, if your temperature drops during an operator break the machine can then make corrections as it starts again to the speed, die time, etc.

Boost Productivity with TOSCAST

TOSCAST offers die casting operators a single point to access, view, and operate. All data collected in TOSCAST can be sent to external networks via dPAQET, further allowing management to improve productivity with centralized data.

If you are interested in exploring how TOSCAST can be tailored to your unique needs and boost productivity, contact the experts at Shibaura Machine.

Related Articles View All

Our Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 - As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ...

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools