Robot Integration Simplified With Shibaura Machine

ELK GROVE VILLAGE, IL, June 29, 2022 - Automating tasks with robots has become an increasingly popular option for injection molding manufacturers. From placing inserts into molds to moving parts through post-mold processes, robots provide process stability, faster cycles, and increased efficiency.

With the addition of robots into production, operators are faced with learning new interfaces and in some cases having to replace core elements of their system to accommodate the addition. Shibaura Machine’s injection molding machines all come standard with Euromap 67 Robot Interface which ensures customers an open production system by transmitting the signals between the robot and the machine controller. This allows for new robots to be easily added, allowing for optimized processes and reduced investment costs.

Robot Control Made Easy

The Euromap 67 Robot Interface included on all Shibaura Machine injection molding machines provides communication with the robot of the customer's choice. The communication interface is included and the top of the machine’s stationary platen is pre-drilled for easy mounting of a robot.

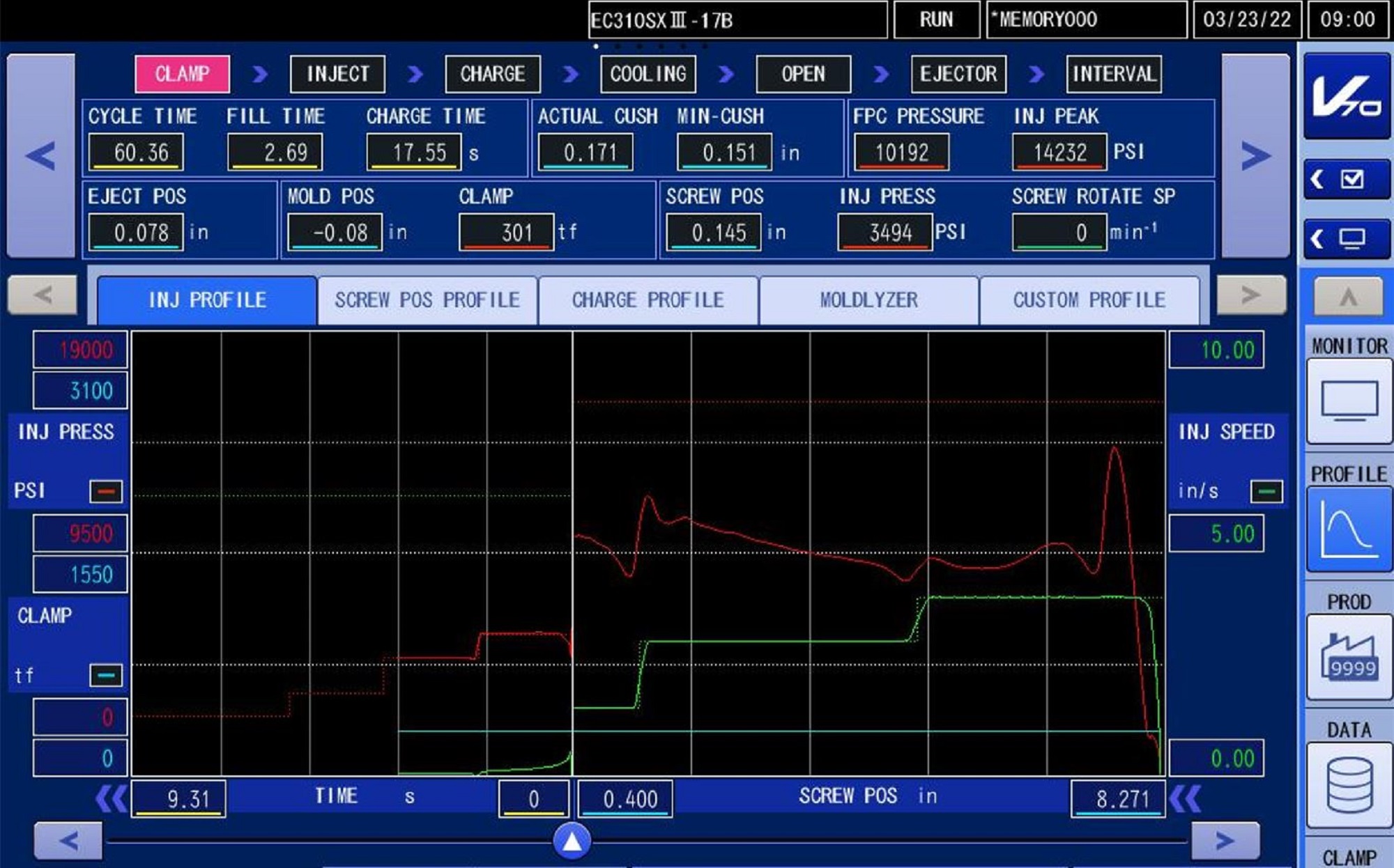

In order to improve ease of integration and exchangeability, customers can also integrate robot controls directly into the V70 controller. Using Shibaura Machine’s VNC robot link, customers can set up, program, and control many industry-leading robot brands including Sepro, Star Automation, and Yushin directly from their main V70 controller. This allows for better management of the molding process and smoother production flow.

Seamless Machine/Robot Integration

Shibaura Machine’s injection molding machines and V70 controller allow for a fully integrated production cell. Both the machine and robot can be controlled and monitored in one place, allowing for a simpler, safer, and easier operator experience.

Contact the Injection Molding team today to learn more!

Tel: (888) 593-1616

Related Articles View All Articles

machiNetCloud Industrial IoT Now Included on New Injection Molding Machines

ELK GROVE VILLAGE, IL, June 22, 2022 - As the landscape in manufacturing continues to rapidly change due to digitalization, the Industrial Internet of Things (IIoT) brings a great opportunity to gain a competitive advantage in every form of production, inc...

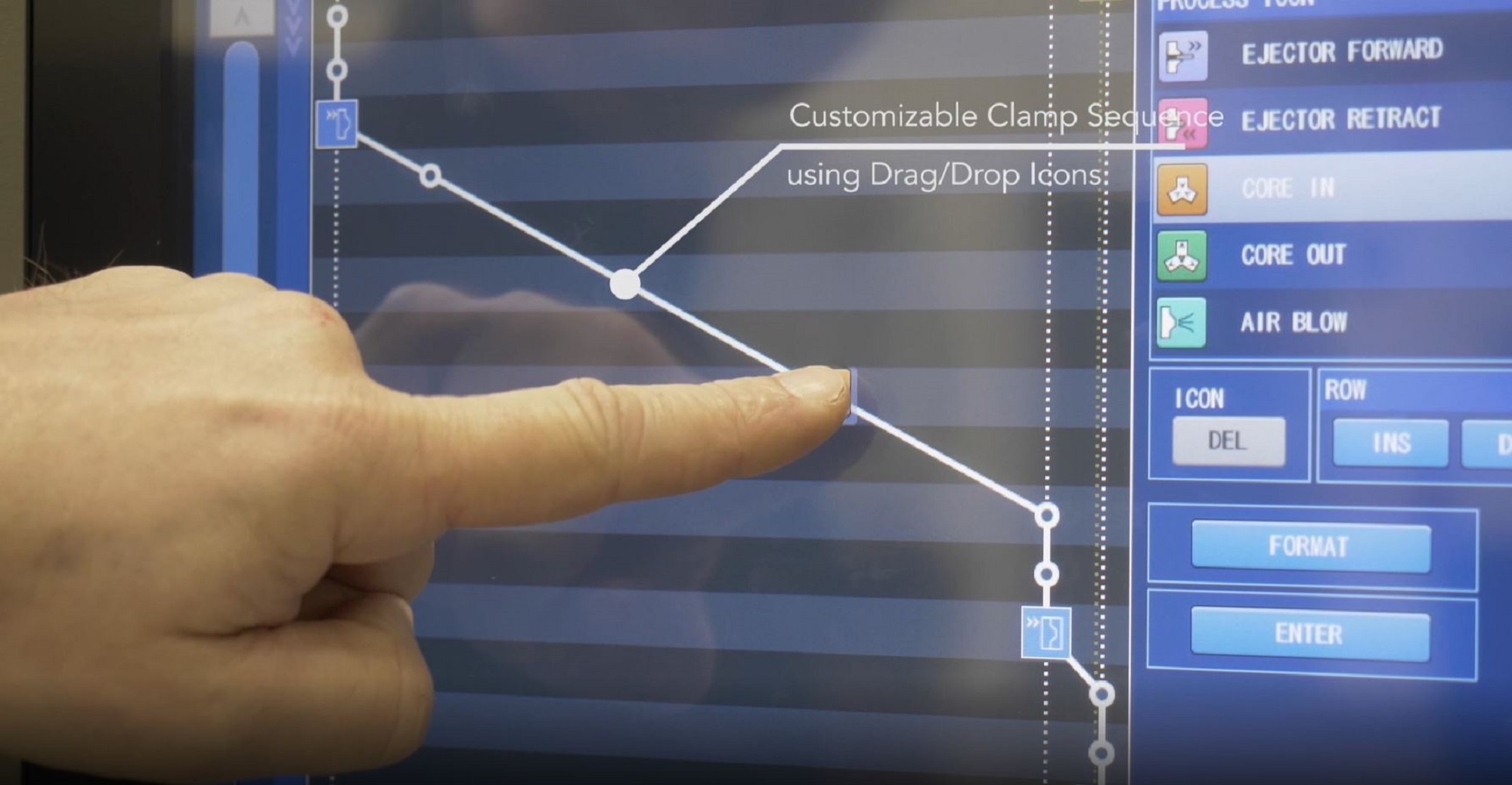

Read moreCustomize Your Clamping Sequence at a Touch

ELK GROVE VILLAGE, IL, June 17, 2022 - One of the steps to get the best results from injection molding requires the operator to properly set up the clamping sequence. Without an intuitive and visual experience, setting this up can be a time-consuming and d...

Read moreRegistration is Open For Our Injection Molding Smart Factory Open House

ELK GROVE VILLAGE, IL, April 28, 2022 - Merging existing technologies with new innovations can be challenging for manufacturers. To help injection molding factories envision the future of manufacturing, Shibaura Machine has partnered with key industry part...

Read more4 Ways to Ensure Precision Filling Transfer Using Final Pack Control

ELK GROVE VILLAGE, IL, March 24, 2022 - The more you can control your production conditions in injection molding the more repeatable your results. When it comes to transfer from the filling stage to packing it might be considered the most crucial element o...

Read moreHow to Establish Optimum Fill Time with Precise Control

ELK GROVE VILLAGE, IL, March 16, 2022 - When it comes to injection molding, the filling stage is critical. Filling too fast in order to save time or reduce the process cycle can end up causing gas to become trapped in the vents. Filling too slowly or fast ...

Read moreImprove Product Quality with Better Screw Speed and Back Pressure Control

ELK GROVE VILLAGE, IL, March 9, 2022 - When it comes to improving part quality and cycle times, don’t underestimate the power of proper control of back pressure and screw rotation. Together, these two functions have a major influence on an injection moldin...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools